Nov 20, 2019

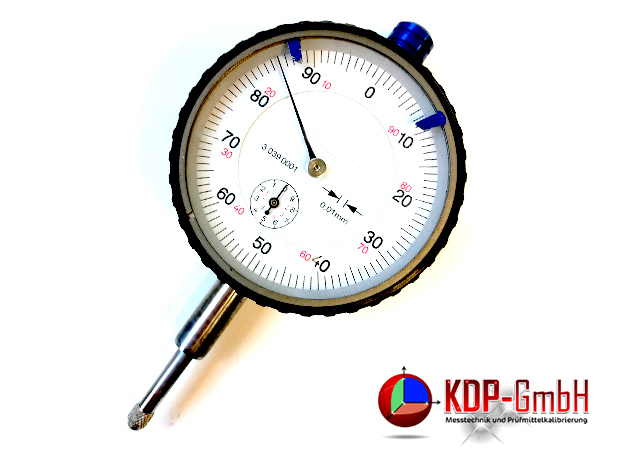

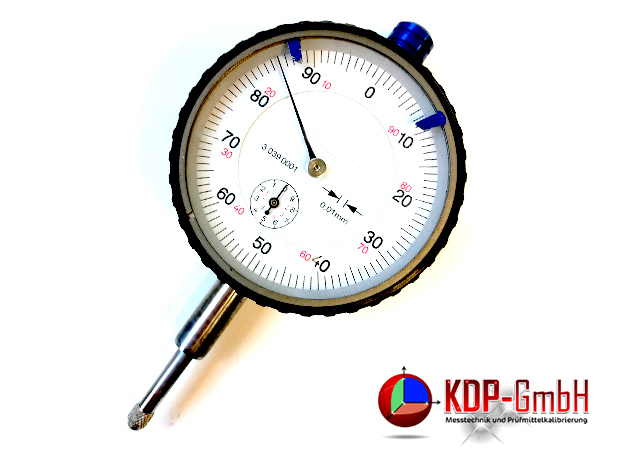

Length or differences in length are measurend with a dial gauge. It can be used for comparative, flatness, positional or concentricity measurements.

Dial gauges exist with analogue or digital display. Setup and function are standardized by DIN regulation 878.

Dial gauges with round scale and analogue display transmit the longitudinal movement of the measuring probe with a toothed rack and gear to the pointer. As a result, the pointer of the dial gauge rotates several times in a circle. The number of revolutions is indicated by a second pointer, similar to the hour hand of a watch.

The advantage of the gear rack transmission is the relatively large measuring range. The disadvantage is, that if the measuring distance greatly exceeds the travel range of the rack, it might lead to gear damage or rack damagein case of a rigid locking of the dial gauge.

Alternativly there are dial gauges with slave pointer with a delayed point of return. However this kind of dial gauges cannot carry out measurements with value differences, like concentricity or flatness.

In addition a great advantage of a dial gauge is, that it can be used in pressure and tension mode and that the return of the measuring rod is done with a spring. Therefore the applied measuring force is almost constant.

Most dial gauges achieve an accuracy level of approximately 10 µm and have a measuring range of 5 to 60 mm. A few dial gauges have an accuracy of 1 µm.

Measuring technology: Dial gauge for the measurement of length and differences in length.

Related topics:

This information and services are provided by:

This glossary of plastic industry is provided by PLEXPERT Canada Inc.

Feb 28, 2020

The most accurate mechanical length measurement devices are finger indicators.

They usually have a scale interval of 1 µm.

A lever system transmits the movement of the measuring pin to the pointer via gears and pinions.

This results in no full pointer rotation.

The

finger indicator is the most accurate mechanical length measurement device.

Related topics:

This information and services are provided by:

This glossary of plastic industry is provided by PLEXPERT Canada Inc.

Feb 28, 2020

Checking and calibrating measuring instruments and test equipment can be done with a gauge block.

A gauge block is made of steel, carbide or ceramic.

They can be used as secondary standards for direct measurement.

Each gauge block embody a certain length with a high accuracy.

If needed several blocks can be combined in order to create any dimension that need to be measured.

Gauge Blocks are available in various forms like parallel, angular, spherical or cylindrical.

Measuring Technology:

Gauge Block to calibrate measuring instruments.

Related topics:

This information and services are provided by:

This glossary of plastic industry is provided by PLEXPERT Canada Inc.

Jun 10, 2021

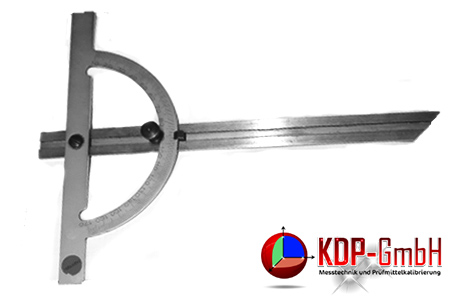

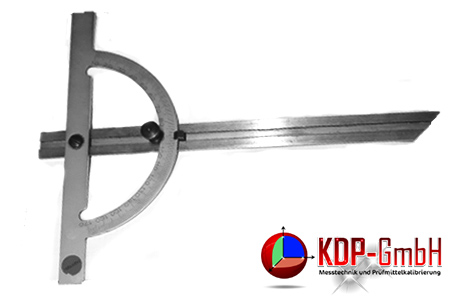

A simple angle measuring instrument or for entering an angle is called goniometer or protractor.

It consists of a circular or semi-circular disc with angular graduation.

The disc is usually made of plastic or sheet metal.

Often goniometers are also integrated in drawing or set squares.

More accurate goniometers have a swivelling rail with a scale with length graduation to milimeters, which can be fixed at the desired angle.

Measuring Technology:

Goniometer with swivelling rail

Related topics:

Dial gauge

This information and services are provided by:

This glossary of plastic industry is provided by PLEXPERT Canada Inc.

Nov 4, 2021

If it is necessary to determine the height of a molded part for a base plate, a height gauge is used for this purpose.

In addition to height measurement, the device can also be used for marking parts to be machined.

In this case, the pointer is sharpened and serves as a scriber.

The measurement determined or set in each case is usually shown on an LCD display.

It should be noted that the height measuring device is placed on a clean and level plate.

Measuring technology: Height Gauge on a metal plate for determining the height of a plastic

part.

Related topics:

Dial Gauge

This glossary of plastic industry is provided by PLEXPERT Canada Inc.