Ejection Side

A mold is usually divided into two sides according to their function.

The side with the ejector pins is called ejection side.

This side is moved for mold opening, therefore another common name is “movable side”.

Related topics:

A mold is usually divided into two sides according to their function.

The side with the ejector pins is called ejection side.

This side is moved for mold opening, therefore another common name is “movable side”.

Related topics:

To get the parts homogeneously and with as least as possible tension out of the cavity, ejectors are used.

Additional ejectors can be set as optimization for the venting system.

The ejectors are mainly axial pins, which are located on the ejector plate and fixed from the ejector holding plate.

The movement of the ejector plate takes place most of the time by hydraulic.

When moving forward, the pins press against the parts and throw them out. The backwards movement is done by hydraulic or spring force.

The movement of the ejectors has a big influence on the wear of the mold.

A mold is usually divided into two sides according to their function.

The side, which is not moving during production is called fixed side.

This side contains the runner system, therefore another common name is “injection side”.

Related topics:

A process where a physical or chemical blowing agent is solved into the polymer melt, which leads to the melt foaming and expanding in the cavity.

Due to the gas expansion of the blowing agent, the injected part will have a sandwich structure with a foamed core and compact skin layers.

The gas pressure inside the part can shorten or completely substitute the holding phase of the injection process, which leads to shorter cycle times.

With this process, part properties such as lesser warpage as well as part weight reduction can be realized. With process-optimized part design, part weight reductions and material savings of up to 35% have been realized.

Chemical blowing agents are usually added to plastics as a masterbatch and decompose into blowing gases and solid by-products under heat.

For the metering and mixing of physical blowing agents, such as nitrogen or carbon dioxide, additional equipment and a special screw are required.

Related topics:

This information and services are provided by:

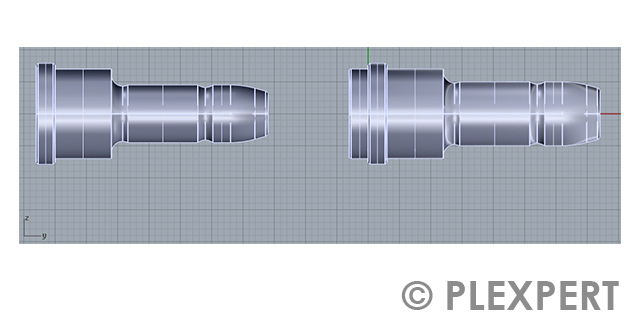

A standard injection mold is split into the injection side and the ejection side.

When the mold is closing, the two halves of the mold are centered through the guide pillars.

In most cases, the guide pillars are fixed on the injection side.

The ejection side moves along with the guide pillars till the mold is completely closed.

In order to make the movement of the other half of the mold easier, guide pillars can have oil grooves.

Depending on the mold layout, guide pillars can have a centering collar to increase stability.

Four guide pillars will be used in one mold.

It has to be noted that the diameter of the guide pillars varies.

Three of them have the same diameter, one of them has a different one.

This is to make sure the mold cannot be mounted in the wrong way.