A standard injection mold is split into the injection side and the ejection side.

When the mold is closing, the two halves of the mold are centered through the guide pillars.

In most cases, the guide pillars are fixed on the injection side.

The ejection side moves along with the guide pillars till the mold is completely closed.

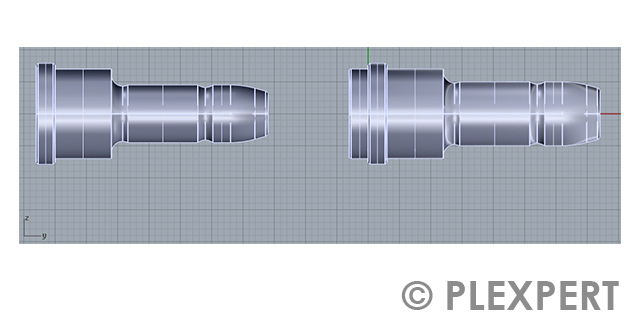

In order to make the movement of the other half of the mold easier, guide pillars can have oil grooves.

Depending on the mold layout, guide pillars can have a centering collar to increase stability.

Four guide pillars will be used in one mold.

It has to be noted that the diameter of the guide pillars varies.

Three of them have the same diameter, one of them has a different one.

This is to make sure the mold cannot be mounted in the wrong way.

Injection Molding: Guide pillar without centering collar left, with collar right.

Related topics: