Cavity pressure can be determined directly, indirectly and contact-free.

Cavity pressure sensors are mostly Piezoelectric Sensors. The directed deformation of a piezoelectric crystal creates an electrical charge. The charge signal, which is proportional to the pressure, is converted into electrical voltage using a charge amplifier. Highly dynamic pressure progressions can be measured using this technology.

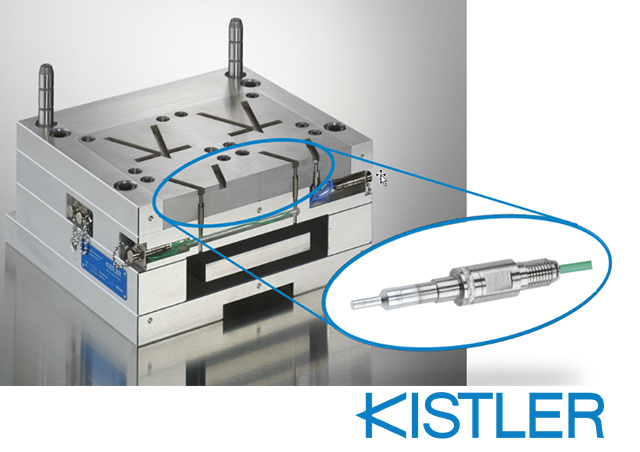

Direct-measuring sensors are in contact with the melt in the cavity, and they measure the pressure without transmission pins. These sensors provide also a very wide pressure range and a very robust design of the sensor.

An advantage of direct pressure sensors is the very accurate measurement of the cavity pressure. On many sensors, the front can be adapted to the surface of the cavity so that no mark can be seen on the part. Combined pressure/temperature sensors measure the cavity pressure and the contact temperature at the same point on the part.

Related topics:

This information and services are provided by: