The machine is pressing the mold halves against each other to counteract the pressure of the melt in injection and packing phase.

The needed force for this is called clamp force.

Most injection molding machines contain this value in their name.

The unit might be displayed in kN or t.

If the clamping force is too low, the mold halves will be pushed away from each other by the melt and flash formation appears.

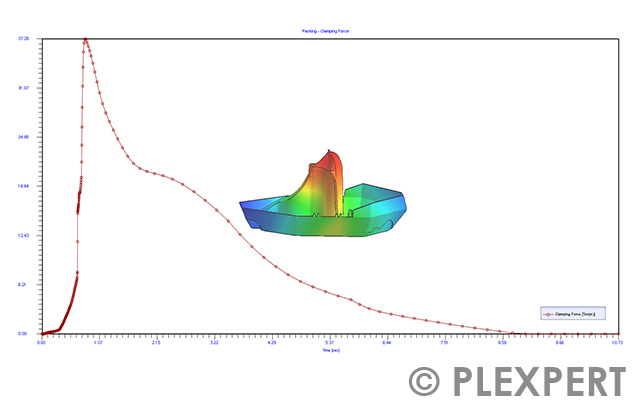

The injection molding simulation helps to determine the necessary clamp force in advance to choose a machine with the correct size.

The clamp force can be estimated by multiplying the projected surface with the cavity pressure.

Injection Molding Machine: The curve of the clamp force helps to choose the correct machine size.

Related topics: