In the injection molding process, it is important that the ejection force does not lead to any deformation of the plastic part.

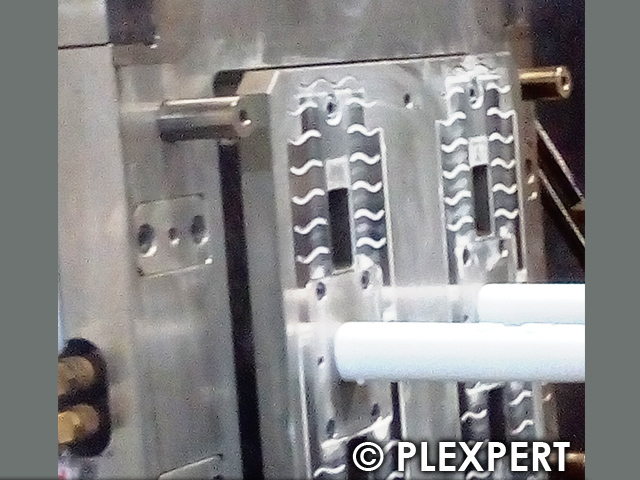

A stripper plate is distributing the applied demolding force from the machine homogeneously along the contact surface and keep the molded part in a defined position during ejection.

Damage of the part as well as marks on the part will be avoided in this way.

Preferably for parts with a deep core, this method is used.

Related topics:

Tool Design

This glossary of plastic industry is provided by PLEXPERT Canada Inc.