The flow behavior of a fluid is described by its type of movement.

A straight forward movement in separated layers with equal temperatures is called laminar flow.

A tube with Reynolds number lower than approximately 4000 will have this kind of flow behavior.

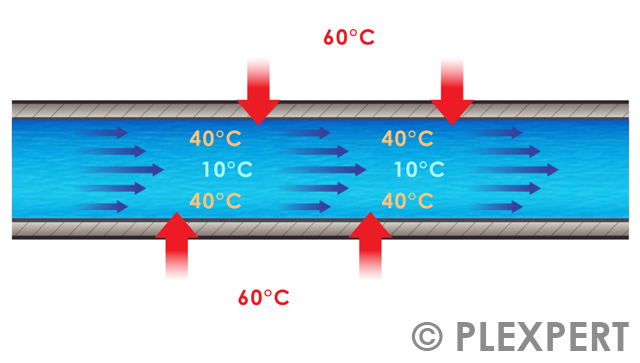

A coolant in injection molding with laminar flow will have its highest temperature near the mold wall.

The lowest temperatures will be found in the center of the cooling channel.

The fluid is heating up from the outside to the inside.

The mold will no longer cool down as soon as the outer layer of the coolant has absorbed the maximum amount of heat.

Because of the laminar flow there is no temperature exchange within the coolant.

The outer layer of the coolant stays hot.

This means that the coolant cannot sufficiently cool the mold anymore.

Therefore, laminar flow is not recommended for a coolant.

Temperature control: Laminar flow inside a cooling channel.

Related topics: