In the injection molding, the melt is injected inside the cavity through a gate.

Therefore, the gate position has an essential influence on the quality of the part.

The route of weld lines, the existence of air traps and the fiber orientation depends on the gate position.

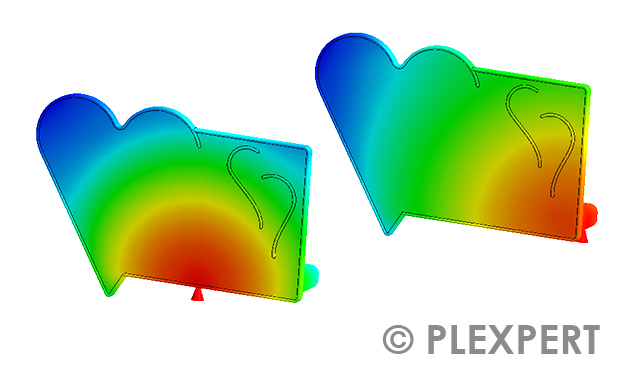

Different flow length affects the pressure that is needed to fill the cavity.

The wall thickness at gate position leads to a longer or shorter packing time.

Moreover, the gate position might change the warpage of a part considerably.

Related topics:

This glossary of plastic industry is provided by PLEXPERT Canada Inc.