In compressed-air systems, a dedicated separation unit removes oil aerosols and fine particles from the airflow. This ensures clean compressed air suitable for sensitive applications where even minimal oil content could cause quality or performance issues. The purification also protects downstream components from wear, thus extending their service life. Filtration and coalescence mechanisms collect and discharge oil droplets effectively. Overall, the device improves operational reliability and maintains stable process conditions.

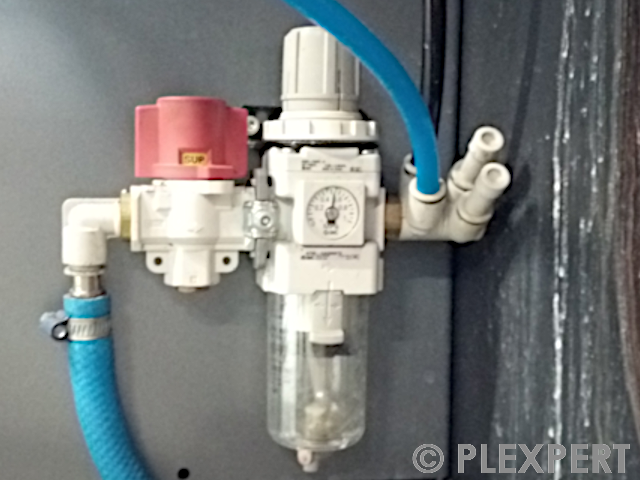

Oil separator on the rear wall of an injection molding machine

Related topics:

Compressed-air dryer

This glossary of plastic industry is provided by PLEXPERT Canada Inc.