Course: Injection molding defects – Discoloration

135.60 $ incl. tax

There are many parts that will be visible while in use.

Either for aesthetic or functional safety reasons, a part shall get its specific color.

Especially if parts will be assembled to one unit later on the color needs to be the same.

Otherwise, the assembly will not meet quality criteria.

Discoloration becomes a possible threat. Therefore, a setter needs to identify the problem and know what to do if discoloration occurs.

You will learn

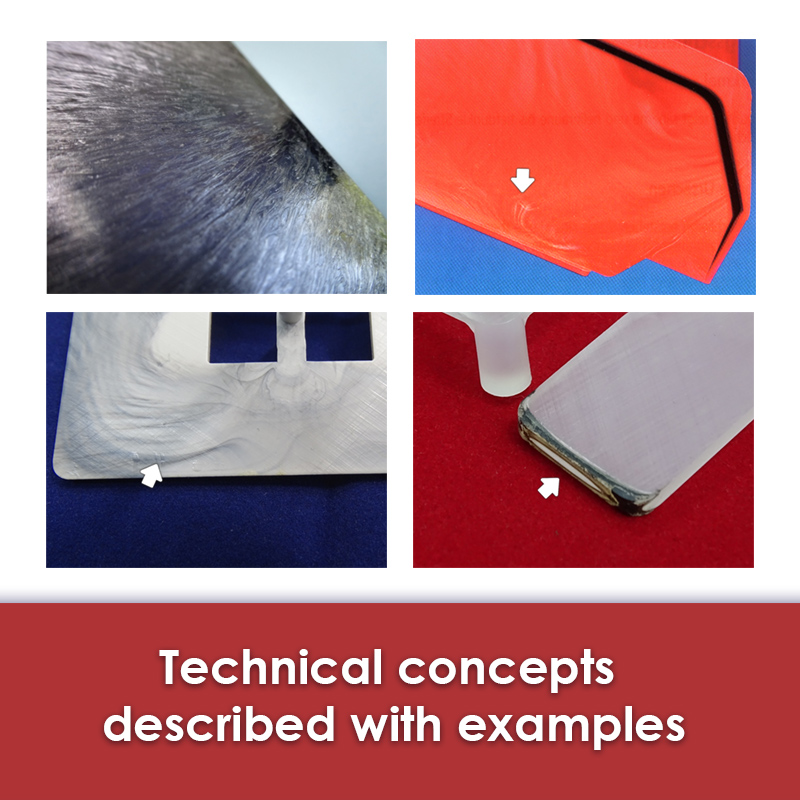

- To identify discoloration

- About the basic principals behind it

- How to solve/avoid the problem

This enables you to

- Select the right set of strategies

- Implement solutions

- Prevent the occurrence of the defect

About the course: Injection molding defects - Discoloration

The setter is not only responsible for the production of a geometrical correct part, but also to ensure the right appearance of the surface.

Very often, plastic parts are colored to have a better appearance in later use.

There are many influencing factors regarding the color on a part.

One problem that could occur is called discoloration.

In this case, the surface of the part does not look favorable anymore and actions need to be applied to act against the problem.

The course shows the basic principles that lead to discoloration. It widens the view and shows what could be done if discoloration can be found in production.

The best measures to solve the problem are discussed in detail.

This course is for

Everyone who is curious about the topic.

This includes especially people working as:

- Setter

- Injection molder

- Quality manager

- Department leader

- Project manager

Course details

For basic skill level |

|

Around 20 min in duration |

|

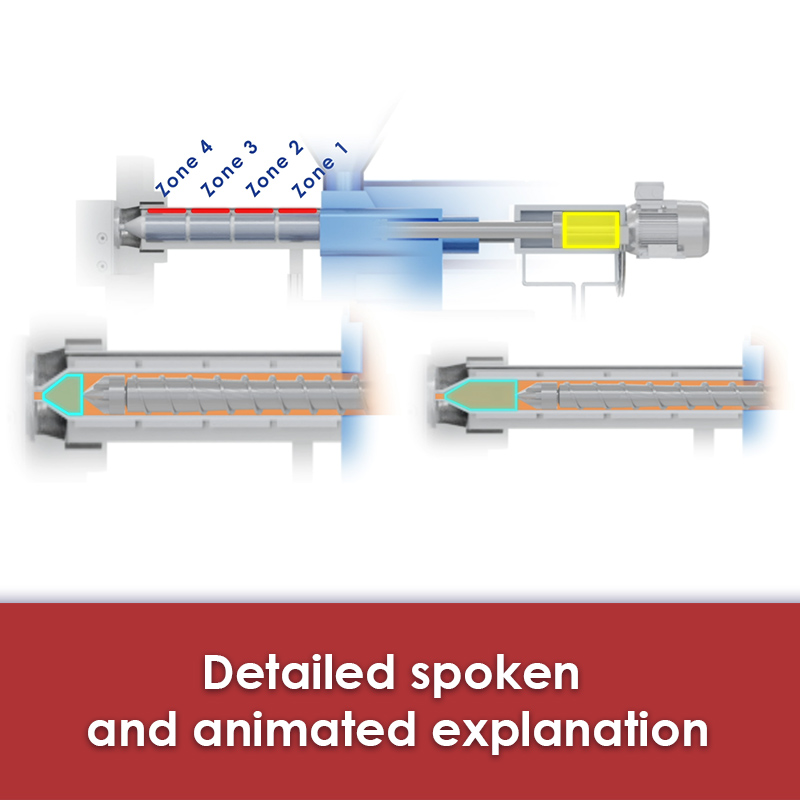

Video On-Demand lessons (1) |

|

Spoken script |

|

Expertise knowledge described step-by-step in text |

|

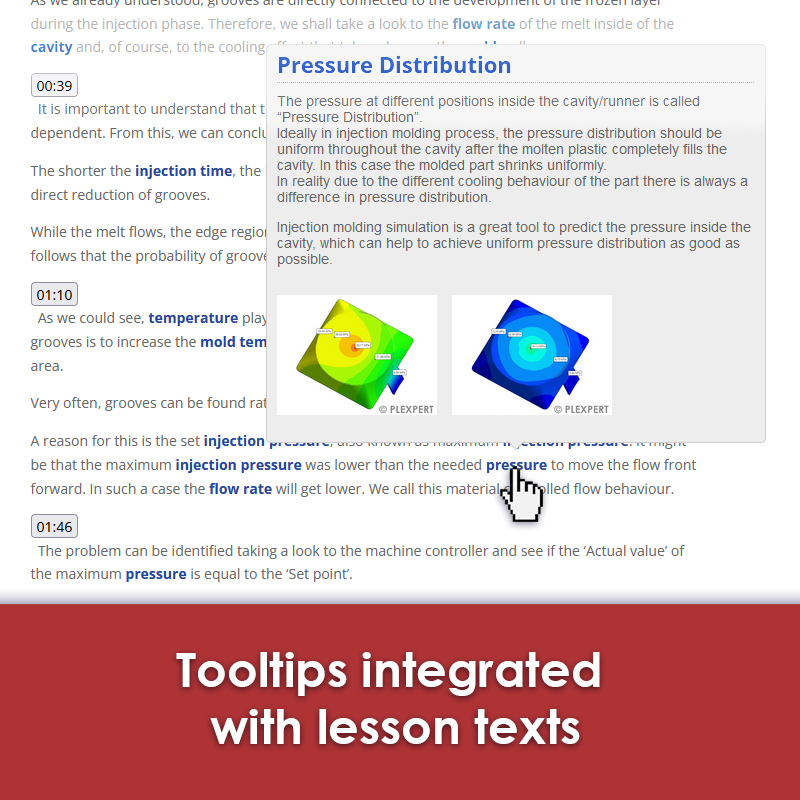

Additional explanations on important technical terms |

|

Full access on computer or mobile for one year |

|

Certificate of completion when you finish the course |

|

(1) Video streaming is part of the e-learning and shall be accessible in your browser.

Course Specialist

CEO at STAK

For many years, Prof. Dipl.-Ing. Peter Wippenbeck has been connected to injection molding technology. He started with mechanical engineering and application technology. Even then, the aim was to achieve a perfect product with the best possible economic efficiency. Quite a few customers confronted him with problem cases and asked for solutions and optimized settings in production.

He took on teaching duties at Aalen University, in Germany, in the field of plastic technology in the 70’s to examine the experiences from industry and to pass on his knowledge to future generations of engineers. Soon, he got a managing position there. His work, with international cooperation, led to the establishment of the master’s degree program in Polymer Technology.

Initiated by the professional association of GKV (called TecPart), industrial training in the field of injection molding was intensified additionally to the engineering degree: Several thousand participants at seminars have already been trained by him and qualified in Aalen including a considerable number of foreign employees and trainers, especially from Thailand, India and Indonesia.

In organizational terms, these activities are located at the Steinbeis Innovationszentrum Kunststofftechnik (SIZK, a non-profit company of Steinbeis Innovation gGmbH), while problem-solving is the responsibility of the Steinbeis Transfer Zentrum Aalen Kunststofftechnik (STAK). In both institutes, the author has been engaged in knowledge transfer in the sense of quality improvement and efficiency in injection molding technology.