Dec 11, 2018

Polymers that get rigid due to curing are called thermosets.

In this process, molecules will crosslink (purple) themselves and form one single makro-molecule.

Because of very strong covalent bonds, the makro-molecule can not be melted again.

Even if high heat is applied, the only result will be degradation.

In contrast to a thermoplast material, the mold for thermoset materials is heated up.

Typical thermoset polymers are phenolics, epoxies and resins.

Dec 19, 2018

In injection molding, the viscosity describes the flow resistance of the plastic in the cavity.

Higher slow-moving of the material means higher viscosity.

Flow curves show that the viscosity of a plastic varies by different shear rates and temperatures.

These curves need to be measured with the help of a viscometer or rheometer.

The viscosity is described by the formulaic character 𝜏 (Tau).

Its unit is Pascal seconds.

Examples of Viscosities:

Water: 0,001 Pas

Oil: 0,03-0,1 Pas

Glycerin: 1,5 Pas

Honey: 10 Pas

Easy flowing plastic melt: 1000-5000 Pas

Heavy flowing plastic melt: 10000 – 100000 Pas

Image 1: Plastic: The temperature curves describe the viscosity over shear rate.

Image 2: Plastic: The higher the viscosity the better the dimensional stability.

Left: A material with higher viscosity; right: lower viscosity.

Related topics:

pvT – Diagram

This information and services are provided by:

This glossary of plastic industry is provided by PLEXPERT Canada Inc.

Dec 19, 2018

The reduction of the specific volume of the part is called volumetric shrinkage.

It takes place inside the mold between injection and ejection.

The thermal contraction is the main reason for the volumetric shrinkage.

For semi crystalline polymers the crystallization is another cause.

High differences in wall thickness and inadequate packing lead to a high volumetric shrinkage.

This results in a high warpage, sink marks and voids.

Dec 6, 2019

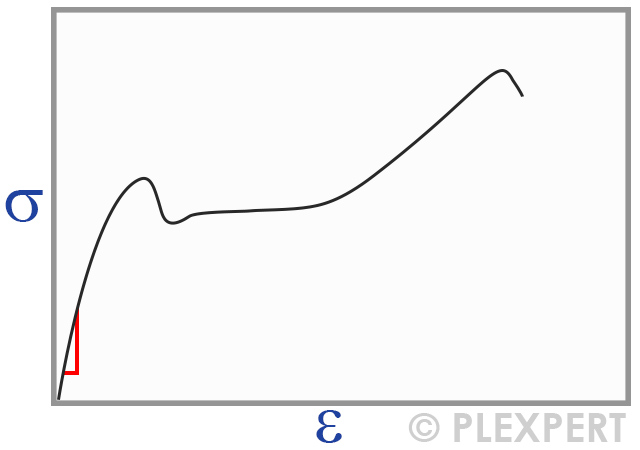

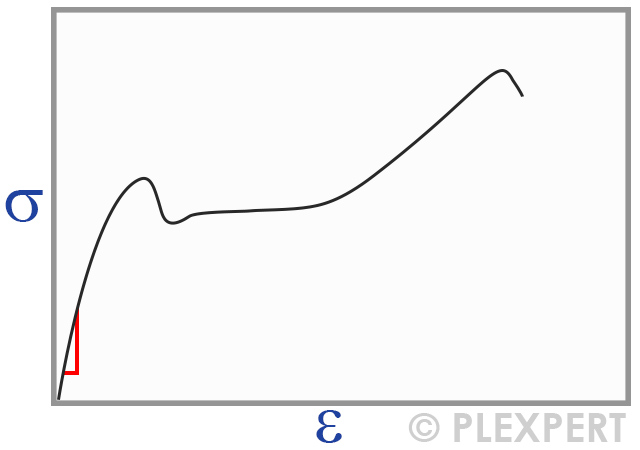

The linear slope of the stress-strain diagram describes the Young’s Modulus of a material.

This reflect the proportional relationship between stress and strain that can be seen by the deformation of a solid body with linear-elastic behavior.

The Young’s Modulus is dependent of the direction and varies therefore especially if anisotropic behavior in a material can be found.

This is also true for cristalline materials.

The higher the Young’s Modulus the more the material resiststhe elastic deformation.

Plastics have a rather small Young’s Modulus compared to steel. In addition to that the modulus depends on temperature as well.

Exmaples at 20 °C:

ABS: 1,9 – 2,6 GPa

PA6: 3,0 – 3,5 GPa

PC: 2,2 – 2,4 GPa

PP: 1,3 – 1,8 GPa

HDPE: 0,5 – 1,2 GPa

Plastic: Stress-strain diagram of a PA6 material with the Young’s Modulus as slope.

Related topics:

This glossary of plastic industry is provided by PLEXPERT Canada Inc.