The transportation of the molten plastic from the injection unit through the mold to the cavity can be done by a hot runner system.

This consists of at least one sprue bushing, the manifold and one or more hot runner gates.

The single components are provided with heaters, which are controlled by suitable PID-Controllers, to achieve a uniform temperature distribution. The system, on the other hand, is thermally decoupled from the mold so that there is a homogeneous heat balance inside the hot runner system.

Advantages of a hot runner system are for example the saving of material and the reduction of the cycle time.

There are different versions of hot runner systems.

The simplest is the hot runner system with thermal lock.

At the end of the injection and packing phase, the melt is cooling down at the gate due to the heat transfer in the colder mold.

The viscosity of the plastic decreases and a “thermal lock” develops, which prevents the melt from entering into the cavity.

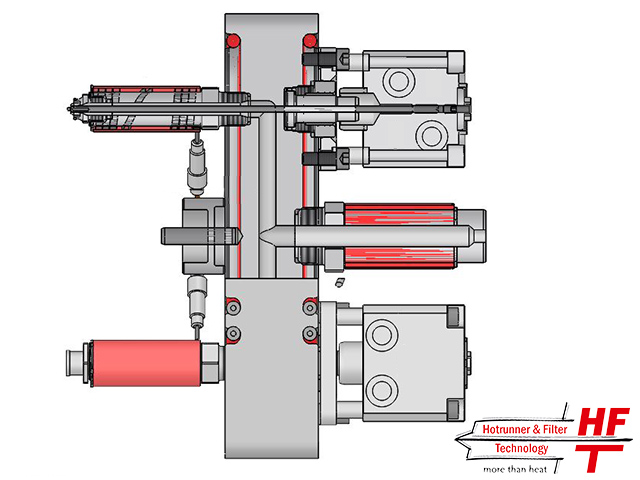

Hot runner systems with valve gates are commonly used.

A needle is added to the gates. It can be moved by cylinders (hydraulic or pneumatic) allowing or preventing the melt to enter the cavity.

Advantages of the usage of valve gates are the controllable filling of the parts and that the break-off point can be designed without a residual pin.

Hot runner: Hot runner system with thermal lock

Hot runner: Hot runner system with valve gates

Related topics:

This information and services are provided by: